- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

The Ultimate Guide to CNC Metal Cutting Machines: Choosing the Right Tool for Your Business

In today's manufacturing landscape, the demand for precision and efficiency has never been higher, making the choice of the right tools crucial for success. Among these, the CNC metal cutting machine stands out as a cornerstone technology for businesses looking to enhance their operational capabilities. According to a recent report by Research and Markets, the global CNC machine market is projected to reach $100 billion by 2025, driven by increasing automation and a shift towards higher precision in metalworking applications. This trend emphasizes the importance of selecting the appropriate CNC metal cutting machine to meet specific production needs. Whether you’re a small workshop or a large-scale manufacturing facility, understanding the nuances of these advanced machines can significantly impact your productivity, cost efficiency, and overall competitiveness in the industry. In this ultimate guide, we will delve into the critical considerations that will help you choose the right CNC metal cutting machine for your business.

Understanding CNC Metal Cutting Machines: Key Features and Benefits

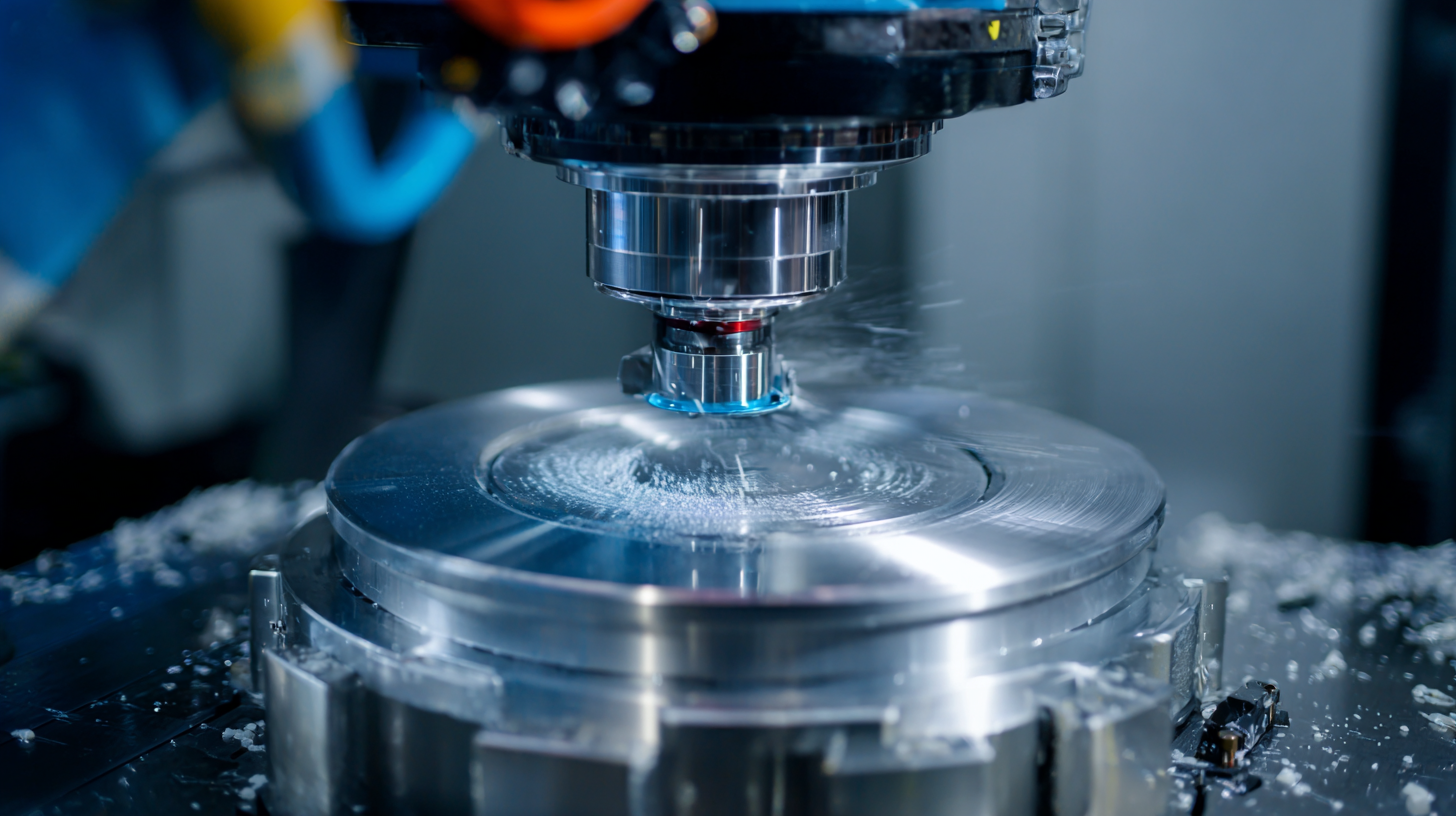

CNC metal cutting machines have become indispensable tools in modern manufacturing, offering unprecedented precision and efficiency. As businesses increasingly shift towards automation, understanding the various types of CNC machines and their functionalities becomes crucial. The key features that differentiate these machines include their cutting technology, such as fiber lasers, CO2 lasers, and solid-state lasers, each with specific advantages for different applications. For instance, fiber lasers are known for their efficiency and speed, making them ideal for high-volume production, while CO2 lasers excel in cutting non-metal materials.

The market for CNC metal cutting machines is experiencing significant growth, with projections indicating an increase from $101.22 billion in 2025 to $195.59 billion by 2032, showcasing a robust compound annual growth rate of 9.9%. This trend reflects not only the rise in demand for high-quality metal products but also the industry's adaptation to more sophisticated technologies. Additionally, the COVID-19 pandemic has prompted a surge in automation across sectors, further driving the need for versatile and reliable CNC machines. As businesses adapt to these changes, selecting the right CNC metal cutting tool becomes essential for staying competitive in the evolving market landscape.

Evaluating Your Business Needs: Choosing the Right CNC Tool

When it comes to selecting the right CNC metal cutting machine for your business, evaluating your specific needs is paramount. First, consider the types of materials you will be working with. Metals vary significantly in terms of hardness, thickness, and composition, and each CNC machine has its strengths. For example, if your operations primarily involve softer metals like aluminum, a less powerful, more cost-effective router may suffice. Conversely, for tougher materials such as stainless steel or titanium, investing in a high-precision laser cutter or plasma cutter is essential to achieve the desired precision and efficiency.

Additionally, think about the scale and volume of your production. Smaller shops may benefit from versatile machines that can handle various tasks, while larger operations might require specialized tools that maximize throughput. Always assess your budget relative to the potential return on investment; a more expensive machine might save costs in the long run through improved productivity. Taking the time to evaluate your business needs thoroughly will enable you to choose a CNC tool that enhances your capabilities and drives growth.

The Ultimate Guide to CNC Metal Cutting Machines: Data Analysis of Machine Types

Common Types of CNC Metal Cutting Machines and Their Applications

When it comes to CNC metal cutting machines, understanding the various types available on the market is essential for selecting the right tool for your business. Common types include laser cutting machines, plasma cutters, and waterjet cutters, each catering to different applications based on the material and required precision. Laser cutting machines, for example, are ideal for projects that involve intricate designs and thin materials, while plasma cutters excel in cutting thick metals with speed and efficiency. Waterjet cutters, on the other hand, provide a cold cutting process, making them suitable for heat-sensitive materials.

The growth of the metal fabrication equipment market reflects the increasing demand for these advanced machines. The global CNC machine market is projected to grow significantly, driven by the rise of automation and precision manufacturing. Industries such as aerospace, automotive, and electronics are particularly reliant on CNC technology to streamline operations and improve product quality. As businesses continue to invest in CNC metal cutting machines, understanding their features and applications will enable manufacturers to optimize their production processes and stay competitive in a fast-evolving market.

Cost Considerations: Balancing Quality and Budget for CNC Machines

When considering the purchase of CNC metal cutting machines for your business, cost is a significant factor that demands careful balancing with quality. A well-chosen CNC machine can streamline your production process, enhance precision, and ultimately boost profitability. However, navigating the plethora of options available can be overwhelming, especially for those on a tight budget. The key is to identify machines that provide the best value without compromising essential features.

For businesses that are just starting or looking to expand, the Anet 4540 desktop CNC and engraving machine stands out as an excellent choice. It combines affordability with the capability to mill larger objects, making it a versatile tool for both hobbyists and professionals alike. By investing in equipment like this, you can harness the advantages of CNC technology without draining your budget.

Alongside this, exploring budget-friendly home gym equipment may seem unrelated, but the same principles apply—quality and functionality should always be prioritized even when seeking the best deals. In 2025, as you navigate through the best budget options, remember to assess the long-term value each machine brings to your operations.

Maintenance and Support: Ensuring Longevity of Your CNC Equipment

When investing in CNC metal cutting machines, maintenance and support play a pivotal role in ensuring the longevity and productivity of your equipment. Regular maintenance not only extends the life of your machines but also helps you avoid costly repairs and downtime. Establish a routine maintenance schedule to inspect, clean, and lubricate your CNC equipment, following the manufacturer's guidelines.

**Tips for Effective Maintenance:**

1. **Daily Checks:** Take a few minutes each day to inspect your CNC machine for any signs of wear and tear. Look for loose wires, leaks, and debris accumulation to prevent minor issues from escalating.

2. **Software Updates:** Regularly update the software of your CNC machines. This helps in fixing bugs and improving the functionality, ensuring your machines operate at peak performance.

3. **Professional Support:** Don’t hesitate to seek professional support when needed. Having a reliable service provider on standby can ensure that any technical issues are resolved quickly and efficiently, minimizing downtime.

By prioritizing maintenance and establishing a solid support system, you can maximize the efficiency and lifespan of your CNC metal cutting machines, ultimately benefiting your business in the long run.

The Ultimate Guide to CNC Metal Cutting Machines: Choosing the Right Tool for Your Business - Maintenance and Support: Ensuring Longevity of Your CNC Equipment

| Dimension | Description | Importance | Maintenance Tips |

|---|---|---|---|

| Cutting Speed | The speed at which the cutter moves through the material. | Affects production efficiency and surface finish. | Regularly check and calibrate machine settings. |

| Feed Rate | The rate at which the material is fed into the cutter. | Influences tool wear and power consumption. | Monitor tool wear signals and adjust accordingly. |

| Tool Material | Material of the CNC cutting tool (e.g., carbide, high-speed steel). | Determines cutting ability and tool lifespan. | Choose the right tool material for the specific application. |

| Lubrication | Use of cutting fluids to minimize friction and heat. | Essential for prolonging tool life and ensuring cut quality. | Regularly check fluid levels and change fluids as per schedule. |

| Machine Calibration | Periodic adjustment of machine settings for accuracy. | Critical for maintaining precision in cutting. | Implement a routine calibration schedule and record results. |