- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

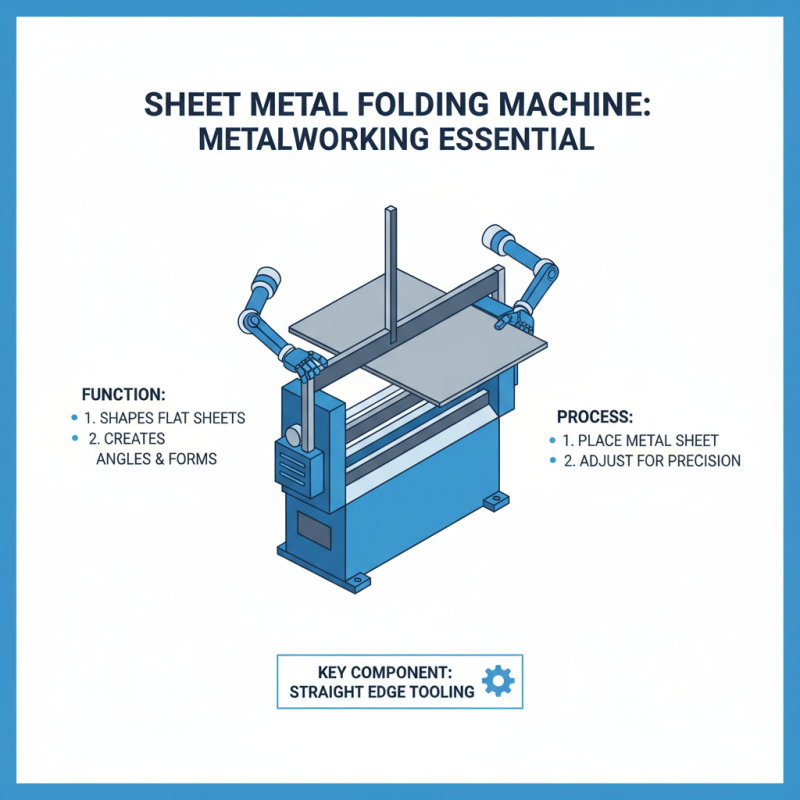

What is a sheet metal folding machine and how does it work?

A sheet metal folding machine is an essential tool in metalworking. It is designed to bend, fold, and shape metal sheets with precision. This machine plays a crucial role in manufacturing industries, where metal components are often required. Understanding how a sheet metal folding machine functions can reveal its significance in various projects.

These machines use mechanical or hydraulic forces to apply pressure on the metal sheets. The operator adjusts settings to create specific angles or curves. Various types of sheet metal folding machines exist, each suited for different tasks. For example, some models can handle thicker materials, while others are better for lighter sheets. A well-maintained machine can significantly enhance production efficiency.

However, there are challenges. Operator skill is vital for achieving accurate results. Improper setup can lead to defects and wasted materials. Furthermore, ensuring safety during operation is critical. Training is essential, as mistakes can be costly. Understanding these aspects can improve the effectiveness of a sheet metal folding machine in any workshop.

What is a Sheet Metal Folding Machine?

A sheet metal folding machine is essential in metalworking. It shapes flat sheets of metal into desired angles and forms. This machine uses a straight edge, known as the tooling, to bend material. Operators place sheets in the machine, adjusting settings for precision.

During operation, the machine exerts force on the metal. The sheet is placed against the die and bent along the desired line. Metal can be folded at various angles. Sometimes, achieving the perfect bend is challenging. Human error or machine misalignment can lead to flaws. It requires practice to master the machine's controls.

Different types of folding machines exist. Each varies in complexity and size. Some machines are manual, while others are fully automated. Understanding the capabilities of each type is crucial. Not every machine suits all metal types or thicknesses. Adjustments must be made for optimal results, which may take time to learn.

Common Types of Sheet Metal Folding Machines

Sheet metal folding machines are essential in metal fabrication. They come in various types, each suited for specific tasks. The most common types include mechanical folders, hydraulic folders, and CNC (Computer Numerical Control) folders.

Mechanical folders are often simpler and more cost-effective. They are great for small-scale operations. However, they may lack precision and speed when compared to other models.

Hydraulic folding machines are widely favored in industry settings. They offer improved force, allowing for thicker materials to be bent easily. According to industry reports, 70% of manufacturers prefer hydraulic models for their reliable performance.

CNC machines, on the other hand, provide unmatched precision. They automate the bending process, reducing human error. This level of accuracy can lead to a 20% increase in productivity.

While various options exist, choosing the right machine can be challenging. Each type has its pros and cons. For instance, hydraulic machines may require more maintenance than mechanical units. Moreover, the initial investment for CNC folders can be significant. Hence, understanding specific needs is crucial for making an informed choice. Manufacturers must weigh their options carefully.

How Sheet Metal Folding Machines Operate

Sheet metal folding machines are essential in modern manufacturing. They transform flat sheets into intricate shapes with precision. These machines use a process called bending, where a sheet is forced into a desired angle using a punch and die. The machine applies pressure until the metal deforms at a specific location.

Understanding how these machines operate can enhance their efficiency. Operators must ensure that the material is correctly placed. Misalignment can lead to poor quality bends. Pressure settings also play a crucial role. If pressure is too high, it might lead to cracks. If too low, the bend may not form correctly. In fact, reports have shown that improper pressure can result in a 15% waste rate of materials.

Tips for operating sheet metal folding machines include regularly inspecting tools and maintaining a clean workspace. A lack of proper upkeep can lead to machine downtime. Operators should also monitor their bending angle consistently. Small variations can cause significant issues down the line, affecting the product's overall quality. Remember, even experienced operators can overlook these details, so it's important to stay vigilant.

What is a sheet metal folding machine and how does it work? - How Sheet Metal Folding Machines Operate

| Feature | Description |

|---|---|

| Machine Type | Hydraulic, Pneumatic, Mechanical |

| Max Sheet Thickness | 0.5mm to 20mm |

| Bending Angle | 0° to 180° |

| Working Width | Up to 4 meters |

| Control System | Manual, CNC |

| Main Applications | Automotive, Construction, HVAC, Electronics |

| Safety Features | Emergency Stop, Safety Guards, Light Curtains |

| Maintenance Requirements | Regular Lubrication, Calibration, Inspection |

Key Components of a Sheet Metal Folding Machine

A sheet metal folding machine is essential in manufacturing. It bends metal sheets into specific shapes for various applications. Understanding its key components can enhance its usage and functionality.

The primary component is the bending beam. This part accurately bends the metal at a controlled angle. It should have a sturdy construction to withstand pressure. Another crucial element is the clamping system. This secures the sheet in place, preventing slips during the bending process. The precision of the clamping directly affects the output quality.

Tips: Regular maintenance of these components is vital. Check bolts and nuts periodically. Ensure the clamping system is adjusted correctly. A small misalignment can lead to significant errors.

The drive mechanism powers the machine. It can be hydraulic, mechanical, or electric. Each type has its pros and cons. Depending on the workload, choose wisely. The wrong choice may lead to inefficiency.

Lastly, the control interface allows operators to set parameters and monitor the folding process. Learn to use it effectively. Misunderstandings here can result in defective products. Always double-check settings before starting a job. Keeping these components in mind will enhance performance and reduce mistakes.

Sheet Metal Folding Machine - Key Components and Their Impact

Applications and Benefits of Sheet Metal Folding Machines

Sheet metal folding machines are essential tools in various industries. They shape metal sheets into desired angles and dimensions. These machines utilize a clamping mechanism combined with a folding tool. This process results in precise bends and clean edges. As industries evolve, these machines adapt, but not without challenges. Operators must master the techniques for optimal results.

The applications of sheet metal folding machines are vast. From automotive manufacturing to construction, they play a significant role. In HVAC systems, for example, these machines help create ductwork components. The benefits include enhanced accuracy and reduced manual labor. However, improper handling can lead to defects in the final product.

Metal folding also supports artistic endeavors. Architects and artists use these machines for creative metalwork. The versatility of sheet metal allows for unique designs. Still, the aesthetics should not compromise functionality. Attention to detail is crucial. Inspecting each fold ensures quality and performance.

Related Posts

-

7 Best Practices for Using a Metal Sheet Bending Machine Effectively

-

Maximize Your Efficiency with Advanced Sheet Metal Laser Cutting Machines for Precision Production

-

Top Sheet Metal Folding Machine Buying Guide for Beginners and Expert Users

-

Understanding the Challenges of Operating a Metal Shear Machine

-

How to Choose the Right Sheet Metal Fabrication Machines for Your Business Needs

-

10 Innovative CNC Press Brake Machine Features You Should Know