- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

Why You Need a Press Machine for Your Precision Manufacturing Process

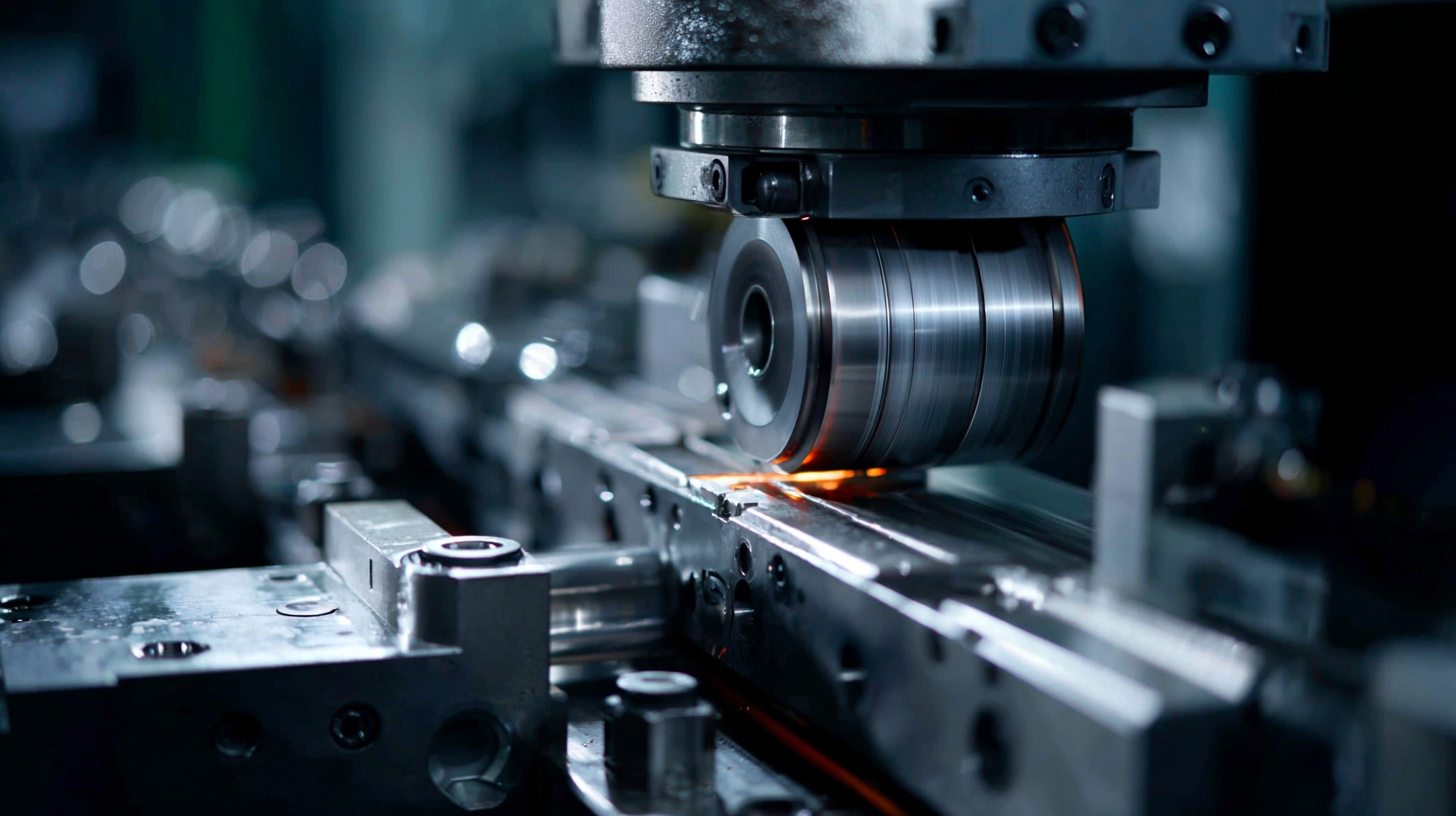

In the realm of precision manufacturing, the role of a press machine cannot be overstated. As companies strive for enhanced productivity and accuracy, experts like John Smith, a leading authority in the manufacturing technology sector, emphasize the necessity of this vital equipment. Smith once stated, "Investing in a high-quality press machine is not just an option; it's a requirement for any manufacturer aiming to maintain a competitive edge in today's market."

The press machine serves as a cornerstone for various manufacturing processes, facilitating the creation of intricate components with unmatched precision. By applying consistent pressure and utilizing advanced control systems, these machines ensure that the end products not only meet specifications but also exceed quality expectations. As industries evolve and demand for precision increases, integrating an efficient press machine into manufacturing workflows becomes essential.

The press machine serves as a cornerstone for various manufacturing processes, facilitating the creation of intricate components with unmatched precision. By applying consistent pressure and utilizing advanced control systems, these machines ensure that the end products not only meet specifications but also exceed quality expectations. As industries evolve and demand for precision increases, integrating an efficient press machine into manufacturing workflows becomes essential.

Furthermore, the versatility of press machines enables manufacturers to adapt to changing market needs swiftly. Whether it's metal stamping, forming, or assembly, the adaptability and efficiency offered by a modern press machine are crucial for any manufacturing entity looking to thrive in a fast-paced environment. In this landscape, having the right tools, particularly a dependable press machine, will undoubtedly shape the future of manufacturing success.

Importance of Precision in Manufacturing: Market Trends and Statistics

The precision manufacturing sector is witnessing remarkable growth driven by the adoption of advanced digital manufacturing technologies and the principles of Industry 4.0. As industries strive for higher efficiency and automation, the smart manufacturing market is projected to surpass USD 600 billion by 2030. This surge is further propelled by the integration of artificial intelligence (AI), the Internet of Things (IoT), and the escalating demand for streamlined processes that enhance productivity.

Additionally, the global precision parts market is expected to grow significantly, with a compound annual growth rate (CAGR) of 9.43% from 2023 to 2029, aiming to reach USD 403.22 billion by 2029. This growth aligns with the increasing emphasis on precision within manufacturing environments, as businesses recognize the essential role precision plays in maintaining competitive advantage. As the market evolves, stakeholders must remain vigilant to geopolitical influences and changing manufacturing sentiments, which will be crucial for strategic planning and operational success in the coming years.

Types of Press Machines: Hydraulic, Mechanical, and Servo-Driven Options

In precision manufacturing, the choice of a press machine can significantly influence production efficiency and product quality. Three main types of press machines are commonly used: hydraulic, mechanical, and servo-driven options. Each type offers unique advantages that cater to different manufacturing needs.

Hydraulic press machines utilize fluid power to achieve high force output, making them ideal for heavy-duty applications. They excel in operations requiring more force over a shorter distance, such as metal forming and stamping. Their adjustable pressure settings offer versatility, allowing manufacturers to use them for a wide range of materials and thicknesses.

Mechanical press machines, on the other hand, rely on a flywheel and mechanical connections. They are known for their speed and can operate at higher production rates compared to hydraulic presses. Mechanical presses are best suited for high-volume production of simpler parts and can ensure uniform results due to their rigid structure and minimal deflection during operation.

Servo-driven press machines combine the benefits of both hydraulic and mechanical systems. They offer precise control over the pressing process, allowing for adjustments in speed, force, and stroke length. This adaptability makes them particularly effective for intricate and detailed operations, providing manufacturers with the ability to enhance productivity while maintaining precision.

Impact of Press Machine Technology on Production Efficiency

The impact of press machine technology on production efficiency is profound, particularly in precision manufacturing. According to a recent report by the Association for Manufacturing Technology, implementing advanced press machines can improve production efficiency by up to 30%. This is largely due to their ability to perform high-speed operations with precision, minimizing waste and reducing the time needed for each cycle. The consistent quality output from these machines ensures that manufacturers can meet stringent specifications without costly rework.

Tips for maximizing the efficiency of your press machines include regular maintenance to avoid unexpected downtimes and leveraging automation to streamline operations. Integrating smart technologies, like IoT sensors, can provide real-time data on machine performance, allowing for proactive adjustments that further enhance efficiency. Additionally, training staff on best practices for operating and troubleshooting press machines can lead to a significant reduction in operational errors, increasing overall productivity.

Furthermore, the flexibility of modern press machines enables them to handle a variety of materials and product designs, which can significantly reduce lead times. Industry surveys indicate that companies utilizing state-of-the-art press technology have noticed a 20% reduction in lead time compared to those relying on traditional methods. This adaptability, combined with improved cycle times, makes investing in press machine technology a strategic move for manufacturers aiming for enhanced production efficiency.

Cost-Benefit Analysis: Investing in Press Machines for Precision Work

Investing in press machines can significantly enhance the efficiency and precision of manufacturing processes. A cost-benefit analysis reveals that companies can reduce production costs by up to 20% when integrating modern press machines into their operations. According to a recent industry report, businesses that employed hydraulic and mechanical press machines saw a marked increase in product quality, with a reported 30% decrease in material waste. This improvement not only contributes to cost savings but also promotes sustainability—a key goal for many manufacturing firms today.

Tips: When considering the purchase of a press machine, evaluate the expected production volume and complexity of your projects. This can help you select a machine that best meets your long-term needs without excessive upfront costs. Additionally, look for machines that offer automation options; reports indicate that automated press machines can yield productivity increases of up to 50%, allowing for smoother operations and faster turnaround times.

Ultimately, the initial investment in quality press machines can lead to substantial savings. For instance, while the capital outlay for advanced equipment may appear daunting, manufacturers can recoup costs within just a year through improved efficiency and lower operational expenses. Embracing such technology not only drives immediate benefits but also positions businesses favorably in a competitive market.

Case Studies: Success Stories from Industries Using Press Machines

In the realm of precision manufacturing, integrating press machines has proven to elevate operational efficiency across various sectors.

Case studies reveal that companies utilizing press machines have significantly improved their production processes, yielding higher accuracy and reducing waste. For instance, in the automotive industry, manufacturers have successfully implemented press machines to create components with intricate designs, resulting in lighter vehicles that maintain structural integrity and enhance fuel efficiency. This innovative approach not only streamlines the manufacturing process but also meets the rising demand for sustainable practices.

Similarly, the consumer electronics sector has benefitted from the adoption of press machines, enabling rapid prototyping and enhanced assembly line productivity. Companies have reported substantial cost savings and reduced time-to-market for new products. These examples underscore the transformative impact press machines have on manufacturing processes, leading to innovative solutions that meet today's complex challenges. As industries continue to evolve, the reliance on advanced machinery like press machines is likely to become ever more critical for achieving precision and efficiency.

Related Posts

-

How to Optimize Your Industrial Press Machine for Maximum Efficiency

-

Maximizing Metal Forming Efficiency: The Evolution and Future of Brake Press Machines in Manufacturing

-

Understanding the Advantages of CNC Metal Cutting Machines in Modern Manufacturing

-

7 Best Practices for Using a Metal Sheet Bending Machine Effectively

-

Revolutionizing Manufacturing: The Future of Sheet Metal Laser Cutting Machines in 2024

-

Understanding the Challenges of Operating a Metal Shear Machine