- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

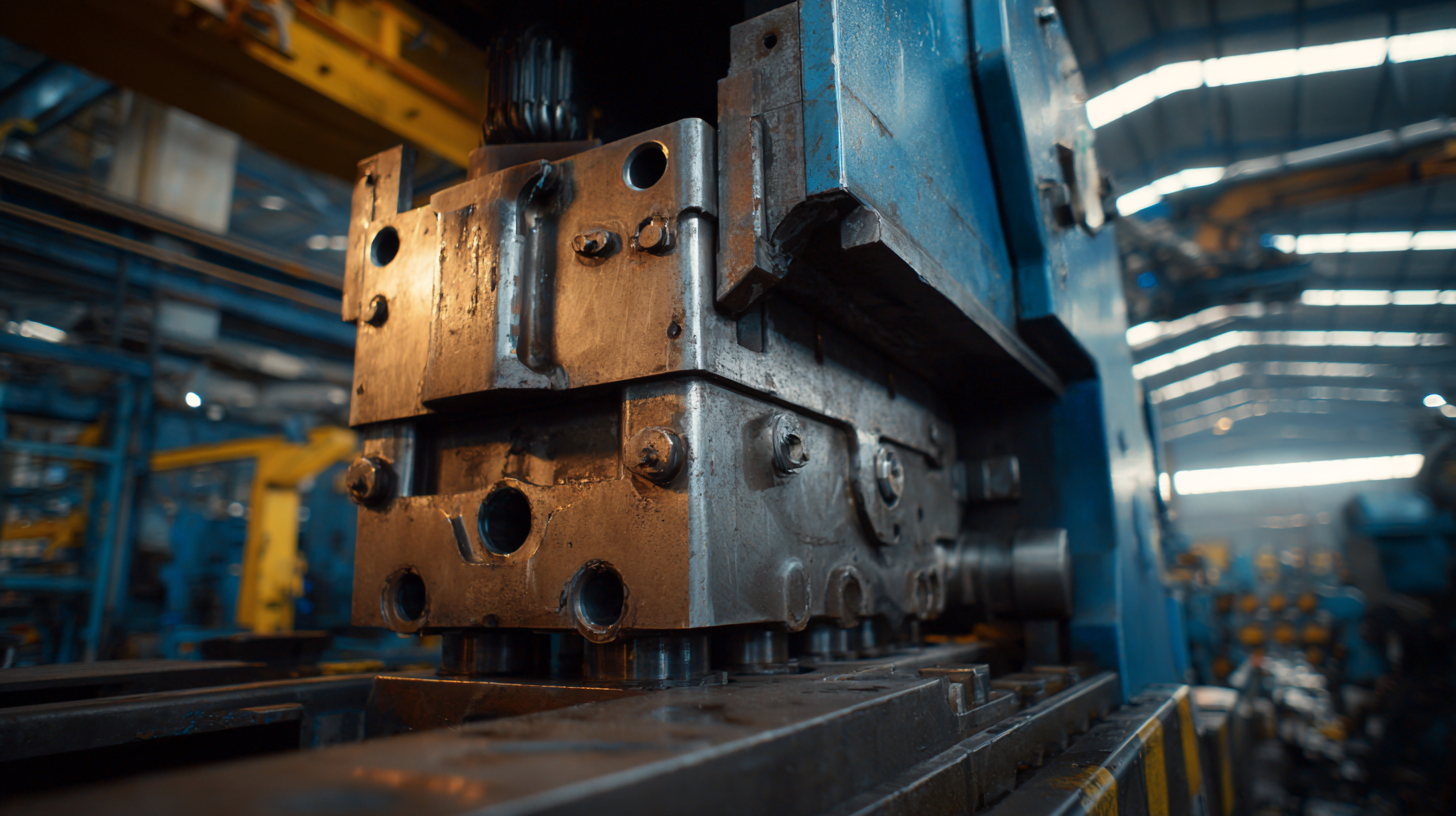

How to Optimize Your Industrial Press Machine for Maximum Efficiency

In the competitive landscape of manufacturing, optimizing the performance of your industrial press machine is crucial for enhancing overall efficiency and reducing operational costs. According to a report by the Manufacturing Institute, companies that implement efficiency optimization strategies can increase productivity by up to 30%. Furthermore, the global industrial machinery market is projected to reach $650 billion by 2025, emphasizing the growing importance of advanced machinery in achieving operational excellence. By focusing on key aspects such as maintenance schedules, proper calibration, and worker training, businesses can ensure their industrial press machines operate at peak performance. This not only leads to increased output but also contributes to lower defect rates and improved product quality. As such, understanding how to effectively optimize these machines is imperative for any organization aiming to remain competitive in this evolving industry.

Understanding the Key Components of Industrial Press Machines for Optimal Performance

Optimizing an industrial press machine requires a thorough understanding of its key components, which play a crucial role in ensuring optimal performance. The main elements include the hydraulic system, the mechanical frame, and the control system. Each of these components must be meticulously maintained and calibrated to function in harmony. Regular inspections can help identify wear and tear that might affect efficiency, preventing unexpected breakdowns.

**Tips:** To enhance the hydraulic system, ensure that oil levels are adequate and that filters are clean. This will prevent contaminant buildup and maintain smooth operation. For the mechanical frame, check for any misalignments or loose bolts that can lead to vibrations, negatively impacting product quality. Lastly, updating the control system software can introduce features that improve precision and reduce cycle time.

Another important aspect of optimizing your press machine is training operators. Ensuring they understand the machine's functions and limitations will lead to better operational decisions. Regular training sessions can help operators become more adept at troubleshooting minor issues before they escalate, thereby maintaining productivity levels.

Optimization of Industrial Press Machine Efficiency

Implementing Advanced Technology for Enhanced Press Machine Efficiency

In the ever-evolving landscape of manufacturing, integrating advanced technology into industrial press machines is crucial for enhancing efficiency. According to a report by McKinsey & Company, companies that adopt automation and advanced analytics can boost their overall labor productivity by up to 20%. By implementing features such as predictive maintenance and real-time monitoring systems, manufacturers can significantly reduce downtime, increase throughput, and prolong the lifespan of their equipment.

In the ever-evolving landscape of manufacturing, integrating advanced technology into industrial press machines is crucial for enhancing efficiency. According to a report by McKinsey & Company, companies that adopt automation and advanced analytics can boost their overall labor productivity by up to 20%. By implementing features such as predictive maintenance and real-time monitoring systems, manufacturers can significantly reduce downtime, increase throughput, and prolong the lifespan of their equipment.

Moreover, technologies such as the Internet of Things (IoT) provide manufacturers with invaluable data insights, enabling them to make informed decisions that optimize operational efficiency. A study by the International Federation of Robotics states that industries deploying IoT solutions in their machinery have seen reductions in production costs by approximately 15%. By utilizing smart sensors and machine learning algorithms, companies can not only fine-tune their press operations but also predict failures before they occur, thereby further streamlining processes and reducing waste. Embracing these advanced technologies is no longer optional but essential for maintaining a competitive edge in the industrial sector.

Regular Maintenance Techniques to Extend the Lifespan of Your Press Machine

Regular maintenance is crucial for extending the lifespan of your industrial press machine and ensuring its optimal performance. One essential technique is to establish a routine inspection schedule where key components such as hydraulic systems, motors, and control units are checked for wear and tear. This proactive approach allows operators to identify potential issues before they escalate, ultimately reducing downtime and repair costs.

In addition to inspections, lubrication is vital in maintaining your press machine. Proper lubrication reduces friction between moving parts and helps prevent overheating, which can lead to severe damage over time. Following the manufacturer’s guidelines on lubrication frequency and types of lubricants is important for achieving the best results. Moreover, cleaning the machine regularly from dust and debris can further enhance its performance and prevent the buildup of contaminants that may interfere with its operation. By prioritizing these maintenance techniques, you can significantly prolong the working life of your press machine while maximizing its efficiency.

Analyzing Production Data to Identify and Eliminate Bottlenecks

To optimize your industrial press machine for maximum efficiency, a crucial step is to analyze production data meticulously. According to a report by the International Journal of Production Research, up to 30% of manufacturing downtime can be attributed to bottlenecks in the production process. This statistic underscores the importance of identifying and mitigating these inefficiencies to ensure smoother operation and increased output.

By employing data analytics tools, manufacturers can gain insights into specific phases of their production lines that are underperforming. For instance, a study by the National Institute of Standards and Technology found that real-time data monitoring can increase overall equipment effectiveness (OEE) by up to 15%. This could involve tracking the speed, quality, and operational availability of the press machines to pinpoint areas of concern.

Once these bottlenecks are identified, strategies such as adjusting machine settings, improving maintenance schedules, or automating specific tasks can be implemented, leading to significant improvements in both production speed and quality.

Training and Empowering Operators for Best Practices in Machine Operation

Training and empowering operators is crucial for optimizing the efficiency of industrial press machines. A well-trained workforce can significantly enhance machine operation by adhering to best practices, which can lead to reduced downtime and improved output quality. Studies indicate that organizations that invest in operator training see a productivity increase of up to 20%, highlighting the importance of education in cultivating skilled personnel. Videos and digital training tools tailored for the specific needs of the machine operators can bridge knowledge gaps, ensuring that every worker is aware of the latest techniques in machine handling.

Moreover, the integration of technology into training can further augment operational effectiveness. For instance, using artificial intelligence for targeted training can yield a 15% improvement in resource utilization, which is critical in a competitive market. These approaches not only prepare operators to manage equipment more effectively but also empower them to identify maintenance issues before they escalate. As industries increasingly adopt digital solutions, the emphasis on continuous learning and skill enhancement will be vital in achieving peak operational performance.

How to Optimize Your Industrial Press Machine for Maximum Efficiency

| Operator Name | Shift | Machine Utilization (%) | Standard Operating Procedure Compliance (%) | Downtime (minutes) | Maintenance Scheduled (Yes/No) | Operator Training Completed (Yes/No) |

|---|---|---|---|---|---|---|

| Alice Johnson | Day | 85 | 90 | 15 | Yes | Yes |

| Bob Smith | Night | 78 | 85 | 25 | No | Yes |

| Carol Davis | Day | 90 | 95 | 10 | Yes | Yes |

| David Lee | Night | 80 | 88 | 20 | No | No |

Related Posts

-

Understanding the Challenges of Operating a Metal Shear Machine

-

Why CNC Press Brakes Are Transforming Sheet Metal Fabrication Efficiency in 2023

-

Ultimate Guide to Mastering Roll to Sheet Cutting Machines for Optimal Production Efficiency

-

7 Best Practices for Using a Metal Sheet Bending Machine Effectively

-

10 Innovative CNC Press Brake Machine Features You Should Know

-

How to Choose the Right Sheet Metal Fabrication Machines for Your Business Needs