- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

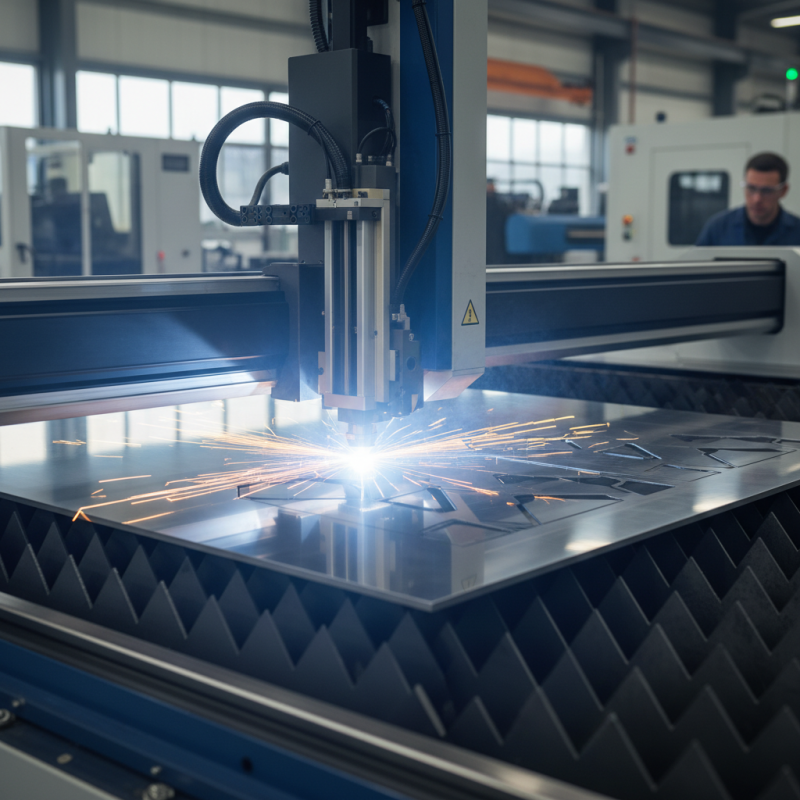

What is a Laser Cutting Machine and How Does it Work?

A laser cutting machine is a powerful tool in modern manufacturing. It uses focused beams of light to cut through various materials, offering precision and speed. This technology has revolutionized industries such as automotive, aerospace, and metalworking.

With a laser cutting machine, intricate designs are easily achieved. The process involves directing a high-energy laser onto the material, effectively melting or vaporizing it. This method provides clean edges and reduces waste. Many industries benefit from the ability to produce complex parts quickly.

However, not every use of a laser cutting machine is perfect. Operators must pay attention to settings, as mistakes can lead to damaged materials. It’s crucial to understand how different materials react to laser cutting. As with any technology, the learning curve can be steep. Embracing these challenges can foster greater expertise in the long run.

What is a Laser Cutting Machine? Definition and Overview

A laser cutting machine is a highly precise tool that uses focused laser beams to cut or engrave materials. Typically, these machines operate by directing a high-powered laser through optics. The energy from the laser melts or vaporizes the material. This process results in clean cuts with minimal edge burn.

According to a recent industry report by Market Research Future, the global laser cutting machine market is projected to exceed $5 billion by 2025. This growth is driven by advancements in technology and increasing demand for automation across industries. Metal fabrication alone accounts for a significant portion of this market. The technology's precision and speed are pivotal in improving production efficiency.

While laser cutting machines offer remarkable advantages, challenges remain. Their high initial cost can be a barrier for small businesses. Additionally, complex materials may require extensive trial and error to optimize settings. Moreover, maintenance is crucial to ensure longevity and performance. This calls for a balance between investment and operational efficiency.

What is a Laser Cutting Machine?

| Dimension | Details |

|---|---|

| Definition | A laser cutting machine is a tool that uses a laser to cut materials, employing a high-powered beam to melt away sections of the material. |

| Working Principle | The machine directs a focused laser beam onto the material, which is melted or vaporized, creating precise cuts. |

| Common Materials | Metals, plastics, wood, fabrics, and leather. |

| Applications | Used in industries such as manufacturing, automotive, aerospace, and signage for precise cutting and engraving. |

| Advantages | High precision, clean cuts, minimal material wastage, and the ability to cut complex shapes. |

| Limitations | Limited thickness capacity for certain materials and higher initial equipment cost compared to other cutting techniques. |

Principles of Laser Cutting Technology: How It Works

Laser cutting technology operates on a simple principle: a focused beam of light cuts through material. The laser generates intense heat, melting or vaporizing the material at the focal point. This process happens so swiftly that the surrounding areas remain unaffected. Different materials require different laser configurations for optimal results. Commonly used materials include metal, wood, and plastics.

When working with laser cutting machines, consider these tips:

- Always choose the right lens for your material. A proper lens can increase precision and reduce waste.

- Maintain your machine regularly to ensure smooth operation. Blockages and dirt can lead to poor cuts.

The quality of the cut also depends on the settings. Adjusting speed and power is crucial. Too high power can cause burning. On the other hand, too little can lead to incomplete cuts. Experimenting with various settings is often necessary to find the ideal balance. Be patient with the process; learning the nuances of laser cutting can take time.

Key Components of a Laser Cutting Machine Explained

A laser cutting machine is an advanced tool that utilizes focused laser beams to cut or engrave materials. Key components play a vital role in its functionality. The laser source generates a concentrated beam of light, which can precisely cut through various materials. This source often uses a gas or solid-state approach to create the laser.

Another essential component is the optics system. It directs the laser beam with mirrors and lenses, allowing it to focus on the material surface. This focus is critical for achieving clean cuts. The machine also features a movement system, which includes motors and gantries to guide the laser head across the material. This system determines the speed and accuracy of the cut.

Despite their effectiveness, these machines do have limitations. Factors such as material thickness and reflective surfaces can impact results. Operators must consider these aspects carefully. Calibration issues may arise, leading to imperfect cuts. Finding the right settings takes time and experimentation. It’s essential to continually learn from these challenges to improve outcomes.

Applications of Laser Cutting Machines Across Various Industries

Laser cutting machines have transformed manufacturing processes across various sectors. Their precision and efficiency have made them a go-to tool in industries like automotive, aerospace, and textiles. In the automotive industry, laser cutting is used for creating intricate parts and components. A report from the International Laser Display Association noted that laser technologies could enhance production speeds by up to 30%. This is significant for companies aiming to reduce costs and improve throughput.

In the aerospace sector, laser cutting machines facilitate the production of lightweight yet durable materials. According to a study by MarketsandMarkets, the aerospace laser cutting market is expected to reach $488 million by 2024. The ability to cut complex geometries with minimal waste is a game-changer. However, the high initial investment can deter smaller firms. Many businesses still struggle with balancing cost and efficiency.

Textile applications also benefit from laser cutting technology. This method allows for detailed designs without fraying edges. A survey conducted by Research and Markets indicates that the global textile laser cutting market will grow significantly. Yet, some manufacturers face challenges. Training operators to handle these advanced machines can be resource-intensive. The learning curve is steep, and not all operators acclimate quickly. These factors require reflection and adaptation in the evolving landscape of laser technology.

Applications of Laser Cutting Machines Across Various Industries

Advantages of Using Laser Cutting Technology in Manufacturing Processes

Laser cutting technology revolutionizes manufacturing. This method offers high precision and efficiency. According to a recent report from MarketsandMarkets, the global laser cutting market is projected to grow significantly, reaching $4.5 billion by 2026.

One major advantage is the reduction in material waste. Unlike traditional methods, laser cutting minimizes excess material. A study by the Fabricators & Manufacturers Association showed that laser cutting can save up to 15% of material costs. This not only helps manufacturers save money but also supports sustainability efforts.

Another benefit is versatility. Laser cutting can work with various materials, including metals, plastics, and textiles. This adaptability allows manufacturers to meet diverse customer demands. However, the initial investment in laser cutting machines can be high. It's crucial for businesses to weigh this cost against long-term savings. Proper training for operators is essential to maximize efficiency and minimize errors.