- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

2026 Best CNC Metal Cutting Machine Reviews and Buying Guide?

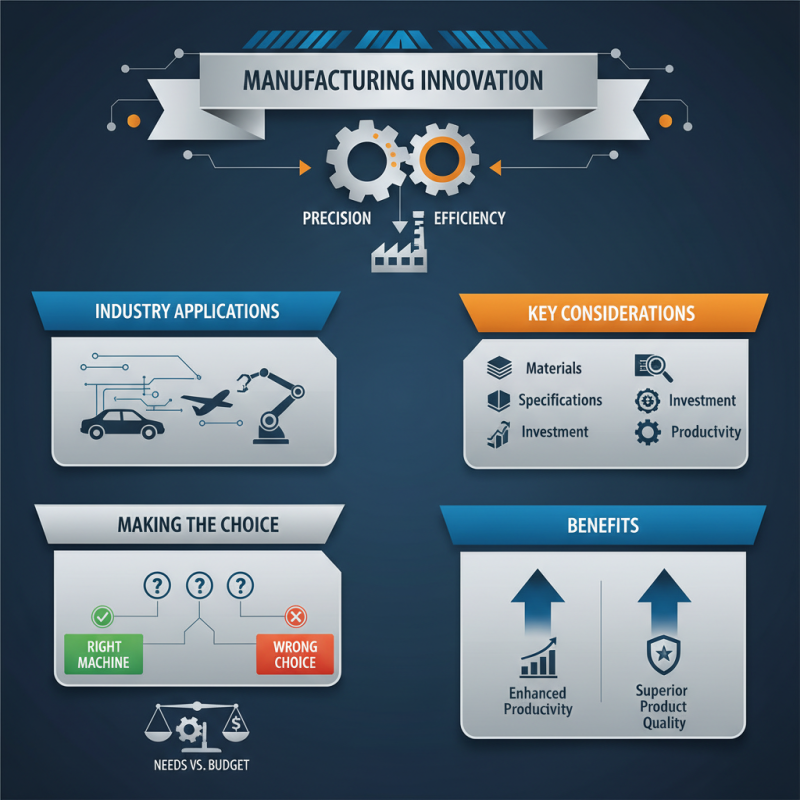

In the world of manufacturing, a CNC metal cutting machine can make a significant difference. These machines deliver precision and efficiency. They are vital for industries ranging from automotive to aerospace. High-quality CNC machines enhance productivity and product quality.

Choosing the right CNC metal cutting machine requires careful consideration. There are numerous options available, and not all are suitable for every business. Each machine has unique features and capabilities. Buyers may feel overwhelmed by the choices.

As you explore various models, reflect on your specific needs. Consider the materials you will cut. Examine the machine's specifications closely. Investing wisely can lead to improved operations. But keep in mind, the wrong choice can waste resources and time. Finding the best CNC metal cutting machine involves balancing needs with budget constraints. It's essential to ask the right questions.

What to Look for When Selecting a CNC Metal Cutting Machine

When selecting a CNC metal cutting machine, consider the type of materials you'll work with. Different machines handle various metals like aluminum, steel, or titanium. If you plan on cutting thick materials, a machine with greater power and better torque is essential. You might want to assess the spindle speed and cutting force as well. These specifications significantly influence cutting efficiency.

Size and workspace are also vital. Ensure the machine fits your shop's layout. A compact design can save space, but it may limit larger projects. Check the weight, too. Heavier machines often provide stability, but they might complicate transport.

Look at the control system as well. User-friendly interfaces can reduce the learning curve. However, more advanced features may offer greater precision. This duality can be a dilemma. Are you willing to invest time to learn, or do you prefer simplicity? Finally, don't forget about maintenance. Regular upkeep ensures longevity, but some machines require more frequent service than others. Balancing these factors requires careful thought.

Top Features of High-Performance CNC Metal Cutting Machines

When selecting a CNC metal cutting machine, key features can significantly enhance performance. High-torque spindle motors allow for precision cuts and faster processing times. According to industry reports, machines equipped with these motors can increase cutting speeds by up to 25%. This speed not only boosts productivity but also improves overall efficiency.

Another important feature is the compatibility with various materials. Advanced CNC machines can handle everything from aluminum to hardened steel. A versatile machine saves time and money, as companies won’t need multiple units for different tasks. However, potential buyers should consider the machine's limitations in material thickness. Some machines struggle with denser materials, leading to potential delays.

Additionally, software integration is crucial. User-friendly interfaces with advanced programming tools streamline operations. A recent survey indicated that 42% of manufacturers cite software difficulties as a major hurdle in CNC operation. As machines become more sophisticated, selecting a model with a robust support system is vital. Yet, not all offerings meet expectations, leading to frustrating user experiences. Buyers must conduct thorough research before making a decision.

2026 Best CNC Metal Cutting Machine Reviews and Buying Guide

| Model | Cutting Area (mm) | Max Cutting Thickness (mm) | Accuracy (mm) | Power (kW) | Price Range (USD) |

|---|---|---|---|---|---|

| Model A | 1500 x 3000 | 10 | 0.05 | 6 | 2000 - 3000 |

| Model B | 2000 x 4000 | 12 | 0.03 | 8 | 3000 - 4000 |

| Model C | 1000 x 2000 | 8 | 0.05 | 5 | 1500 - 2500 |

| Model D | 2500 x 5000 | 15 | 0.04 | 10 | 4000 - 6000 |

Comparison of Popular CNC Metal Cutting Machine Brands in 2026

When looking for the best CNC metal cutting machines in 2026, it's vital to compare various brands. Many options exist in the market, each offering unique features. A recent industry report highlighted that precision and speed are crucial factors influencing buyer decisions. Some brands excel in speed but may lag in accuracy. Others offer excellent accuracy but not the fastest production speeds.

Tips: Assess your project needs first. Do you value speed more than precision? Or the other way around?

Several brands have been recognized for their versatility. Their machines can cut through various metals, from aluminum to steel. A key factor in choosing a CNC machine is its software compatibility. Advanced software can streamline operations significantly. Look for models that support multiple file formats for ease of use.

Tips: Ensure the machine you choose has a user-friendly interface. This can save time during training and operation. Also, consider maintenance costs; some machines require more upkeep than others.

Understanding the trade-offs between cost and features is essential. Advanced features can drive up the price. Balancing these elements can seem daunting. However, informed choices lead to better investments. Always read reviews and seek advice from experienced users. Real user experiences often reveal hidden flaws and advantages.

2026 Best CNC Metal Cutting Machines Performance Comparison

This chart compares various performance metrics of top CNC metal cutting machines in 2026, including cutting speed, precision, maximum thickness capability, and software compatibility. Each machine's metrics are represented in a bar format for easy comparison.

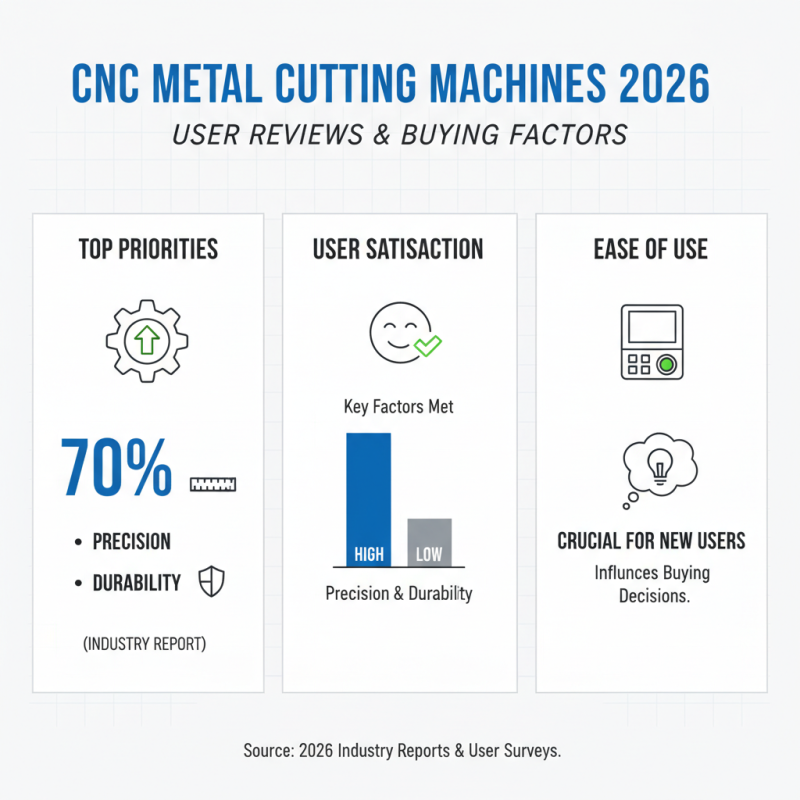

User Reviews and Ratings of Leading CNC Metal Cutting Machines

When considering the best CNC metal cutting machines in 2026, user reviews play a crucial role. Many users express satisfaction with machine precision and durability. According to industry reports, over 70% of users prioritize these factors when making their purchase. Additionally, ease of use significantly influences buying decisions, especially for those new to CNC technology.

Tips: Look for user feedback focusing on reliability. Machines with consistent ratings of four stars or higher usually indicate quality performance.

Despite high ratings, some machines do come with challenges. Users often report difficulty in software integration or lack of customer support. A survey indicated that 40% of buyers experienced issues with installation or initial setup. Always consider these factors before making a choice.

Tips: Research forums and independent reviews for real user experiences. Engage with communities to gather insights that may not be in official product descriptions. This can help ensure a smooth operation in the long run.

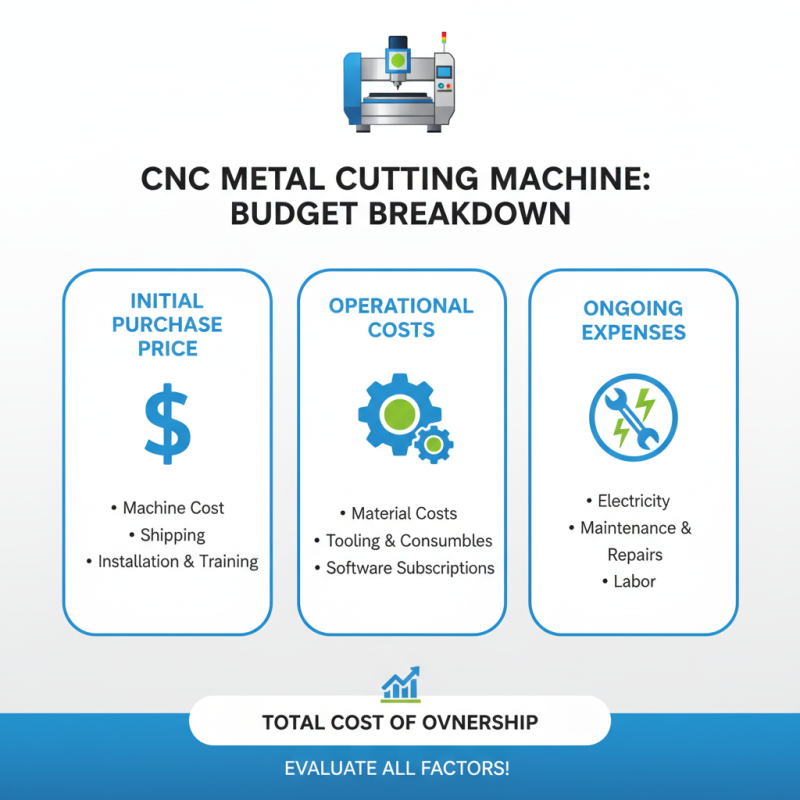

Cost Considerations and Budgeting for CNC Metal Cutting Machines

Budgeting for CNC metal cutting machines involves a careful evaluation of costs. The initial purchase price is just one factor. Consider operational costs, including maintenance and electricity. These expenses can add up over time.

Additionally, factor in training for operators. Skilled workers are essential to maximize machine potential. Training can be costly but vital for efficiency. It's also important to think about the software. Some CNC machines require specific software packages, which can lead to extra costs.

Another aspect to ponder is future upgrades. A machine that meets your current needs might not suffice later. Planning for scalability can be challenging. It's wise to save for potential improvements. Always revisit your budget and expenses after purchasing. Reflecting on these factors helps in making informed decisions.

Related Posts

-

The Ultimate Guide to CNC Metal Cutting Machines: Choosing the Right Tool for Your Business

-

Understanding the Advantages of CNC Metal Cutting Machines in Modern Manufacturing

-

5 Compelling Reasons to Choose a CNC Cutting Machine for Your Business

-

Innovative Solutions for Efficient CNC Press Brake Machine Operations

-

Unlocking Precision: The Future of CNC Cutting Machines in Modern Manufacturing

-

Maximizing Metal Forming Efficiency: The Evolution and Future of Brake Press Machines in Manufacturing