- About US

- IMC

- By Equipment

-

- Manufactures

- Blog

The Best CNC Bending Machine for Precision Metal Fabrication in 2023

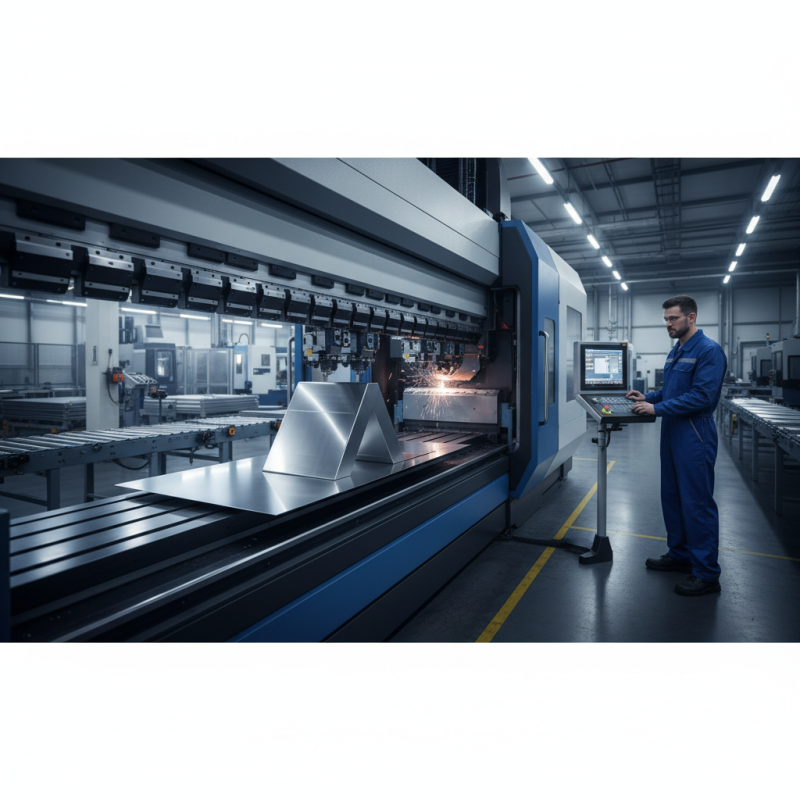

In the world of precision metal fabrication, the CNC bending machine has emerged as an indispensable tool for manufacturers striving for accuracy and efficiency. According to industry expert John Smith, a leader in CNC technology, “The CNC bending machine has revolutionized how we approach metalworking, allowing for unparalleled precision that was once thought impossible.” As we delve into the advancements and capabilities of these machines in 2023, it becomes clear that they play a crucial role in meeting the high demands of modern production.

The latest features and technologies integrated into CNC bending machines are designed to enhance productivity while minimizing errors. With programmable controls, operators can achieve intricate bends and complex geometries that align with stringent specifications required in various industries. The continuous evolution of this machinery not only streamlines the fabrication process but also sets a new standard for quality, enabling businesses to efficiently respond to customer needs.

In this exploration of the best CNC bending machines available in 2023, we will highlight the critical aspects that contribute to their effectiveness in metal fabrication. Understanding these key elements will help manufacturers select the right equipment for their operations, ensuring they remain competitive in an ever-evolving market.

Introduction to CNC Bending Machines and Their Importance in Fabrication

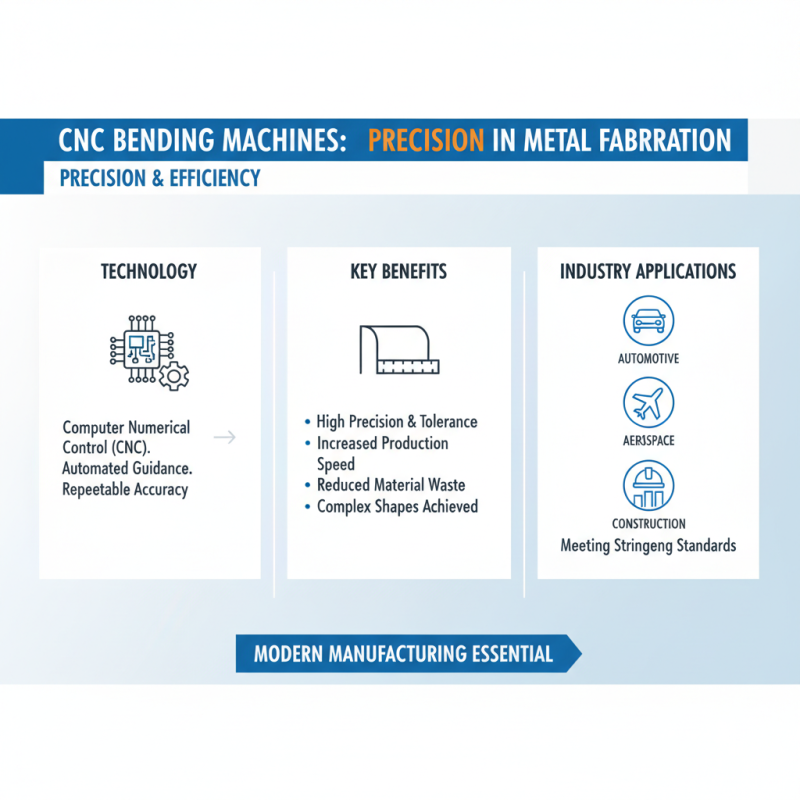

CNC bending machines play a crucial role in the metal fabrication industry, offering precision and efficiency that are essential for modern manufacturing processes. These machines utilize computer numerical control technology to guide the bending operations, allowing for highly accurate shapes and dimensions. This level of precision is vital for industries such as automotive, aerospace, and construction, where the specifications must meet stringent standards to ensure safety and performance.

The importance of CNC bending machines extends beyond mere accuracy; they also enhance productivity. By automating the bending process, these machines reduce the time and labor involved, enabling fabricators to produce complex components consistently. Additionally, CNC bending machines can be programmed for a variety of bending angles and material types, making them adaptable for different projects. This versatility not only streamlines operations but also minimizes material waste, contributing to more sustainable fabrication practices. As such, the integration of CNC bending technology is imperative for any fabrication shop aiming to maintain a competitive edge in the ever-evolving market.

Key Features to Consider When Choosing a CNC Bending Machine

When selecting a CNC bending machine for precision metal fabrication, there are several key features to consider that can significantly impact overall performance and the quality of the final product. First and foremost, the bending capacity of the machine is crucial. This includes the maximum bending angle and the thickness of the material it can handle. Machines with adjustable bending capabilities are often preferred, as they provide versatility for working with various metal types and sizes.

Another important factor is the accuracy of the machine. Precision is critical in metal fabrication, and features such as closed-loop control systems and advanced CNC technology can enhance accuracy. The machine should also have reliable repeatability, ensuring that production runs yield consistent results. Additionally, ease of use should not be overlooked; machines equipped with user-friendly software and interface allow for smoother operation and quicker setup times, which is essential for meeting tight deadlines in a manufacturing environment.

Lastly, consider the build quality and durability of the CNC bending machine. A robust construction not only ensures longevity but also better performance under various operating conditions. Maintenance requirements and service support are also vital; a reputable machine that is easy to maintain will help reduce downtime and keep production running efficiently. By evaluating these features carefully, one can make an informed decision when investing in a CNC bending machine for precision metal fabrication.

The Best CNC Bending Machine for Precision Metal Fabrication in 2023 - Key Features to Consider When Choosing a CNC Bending Machine

| Feature | Description | Importance | Typical Range |

|---|---|---|---|

| Bending Capacity | Maximum thickness and length of material it can bend. | High | Up to 20mm thickness, 4000mm length |

| Accuracy | Precision of bends, affecting overall product quality. | Critical | ±0.5mm |

| Control System | Type of control (manual, CNC, etc.) affecting ease of use. | Moderate | CNC with touch screen |

| Speed | Speed of operation measured in bends per minute. | High | 5-10 bends/min |

| Energy Efficiency | Power consumption compared to output. | Moderate | High efficiency models available |

| Price Range | Cost of the machine. | High | $20,000 - $100,000 |

Top CNC Bending Machines for Precision in 2023

When it comes to precision metal fabrication in 2023, selecting the right CNC bending machine is crucial for achieving accurate and consistent results. The advancements in CNC technology have led to the development of machines that not only increase efficiency but also enhance precision bending capabilities. These machines are equipped with advanced software and controls, allowing operators to execute complex bending tasks with remarkable accuracy. The integration of automation features ensures that the bending process is streamlined, reducing the chances of human error and increasing overall productivity.

Top CNC bending machines available today feature a variety of functionalities tailored for precision work. Key attributes to look for include adjustable bending angles, quick setup times, and robust construction for handling a range of materials. Furthermore, many models now offer user-friendly interfaces and programmable options, enabling users to replicate intricate designs with ease. As a result, these machines empower fabricators to expand their capabilities, ensuring that even the most demanding projects can be completed with precision and efficiency. Investing in a high-quality CNC bending machine will ultimately enhance the quality of work and meet the growing demands of the industry in 2023.

Comparative Analysis of Leading CNC Bending Machine Brands

When it comes to CNC bending machines, precision is key in metal fabrication, and choosing the right brand can significantly impact your workflow and product quality. In 2023, several leading brands have emerged, each bringing their own unique features and technologies to the table. A comparative analysis of these brands reveals trends in accuracy, versatility, and user experience. Some machines are equipped with advanced software that enhances precision, while others focus on heavy-duty construction to support a wider range of materials.

Tips: When evaluating CNC bending machines, consider the tonnage you require for your projects. It's essential to choose a machine that can handle your workload without compromising on precision. Additionally, look for user-friendly interfaces; a machine that is easy to operate can save time and reduce training costs.

Furthermore, after-sales support and warranty services are crucial factors to consider. A brand that offers robust customer service can help minimize downtime, ensuring your operations run smoothly. Investing in a machine with a strong reputation for reliability will pay off in the long run. Whether you need a compact solution for small-scale projects or a more robust option for high-volume production, a detailed comparison of available brands will better inform your decision.

Future Trends in CNC Bending Technology for Metal Fabrication

As we look to the future of CNC bending technology for metal fabrication, several trends are becoming increasingly apparent. One of the most significant developments is the integration of artificial intelligence and machine learning into CNC systems. These technologies are enabling machines to learn from past processes, leading to improved precision and efficiency in metal bending operations. By harnessing vast amounts of data, future CNC bending machines will optimize their performance, reduce errors, and adapt to various material compositions with ease.

Another emerging trend is the growth of automation and robotics in the fabrication process. The seamless collaboration between CNC machines and automated arms or robotic systems is enhancing production capabilities, allowing for faster turnaround times and greater consistency. This integration not only boosts productivity but also frees skilled operators from repetitive tasks, enabling them to focus on more complex and value-added activities.

Tips: When considering investing in a CNC bending machine, look for one that allows for easy software updates and integrates with existing systems. Moreover, prioritize machines that offer training resources, as familiarizing your team with new technology can significantly improve efficiency and reduce downtime. Lastly, evaluate the machine's flexibility in handling different materials and thicknesses to ensure it meets a variety of fabrication needs as your projects evolve.

Related Posts

-

10 Innovative CNC Press Brake Machine Features You Should Know

-

How to Optimize Your CNC Plasma Cutting Machine for Maximum Efficiency and Precision

-

How to Optimize Your Industrial Press Machine for Maximum Efficiency

-

Maximizing Metal Forming Efficiency: The Evolution and Future of Brake Press Machines in Manufacturing

-

Exploring Innovations in CNC Plasma Cutting Machines at the 138th Canton Fair 2025: Industry Insights

-

Innovative Solutions for Efficient CNC Press Brake Machine Operations