In recent years, the global demand for high-quality plastic profile extrusion machines has surged, driven by the rapid growth of various industries such as construction, automotive, and consumer goods.

According to a report by Grand View Research, the global plastic extrusion market size was valued at USD 206.54 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.9% from 2023 to 2030. As buyers increasingly seek innovative and sustainable alternatives to conventional machinery, the focus is shifting towards more efficient and eco-friendly plastic profile extrusion machines.

This guide aims to explore the latest advancements and innovative alternatives available in the market, helping global buyers make informed decisions that align with their operational needs and sustainability goals.

The landscape of plastic profile extrusion is rapidly evolving, driven by innovative technologies that offer sustainable and efficient alternatives to traditional machines. Emerging processes such as additive manufacturing and bio-extrusion are gaining traction among manufacturers seeking to reduce their environmental footprint while improving production efficiency. These technologies not only minimize waste but also enable the use of recyclable and biodegradable materials in the extrusion process, aligning with global trends toward sustainability.

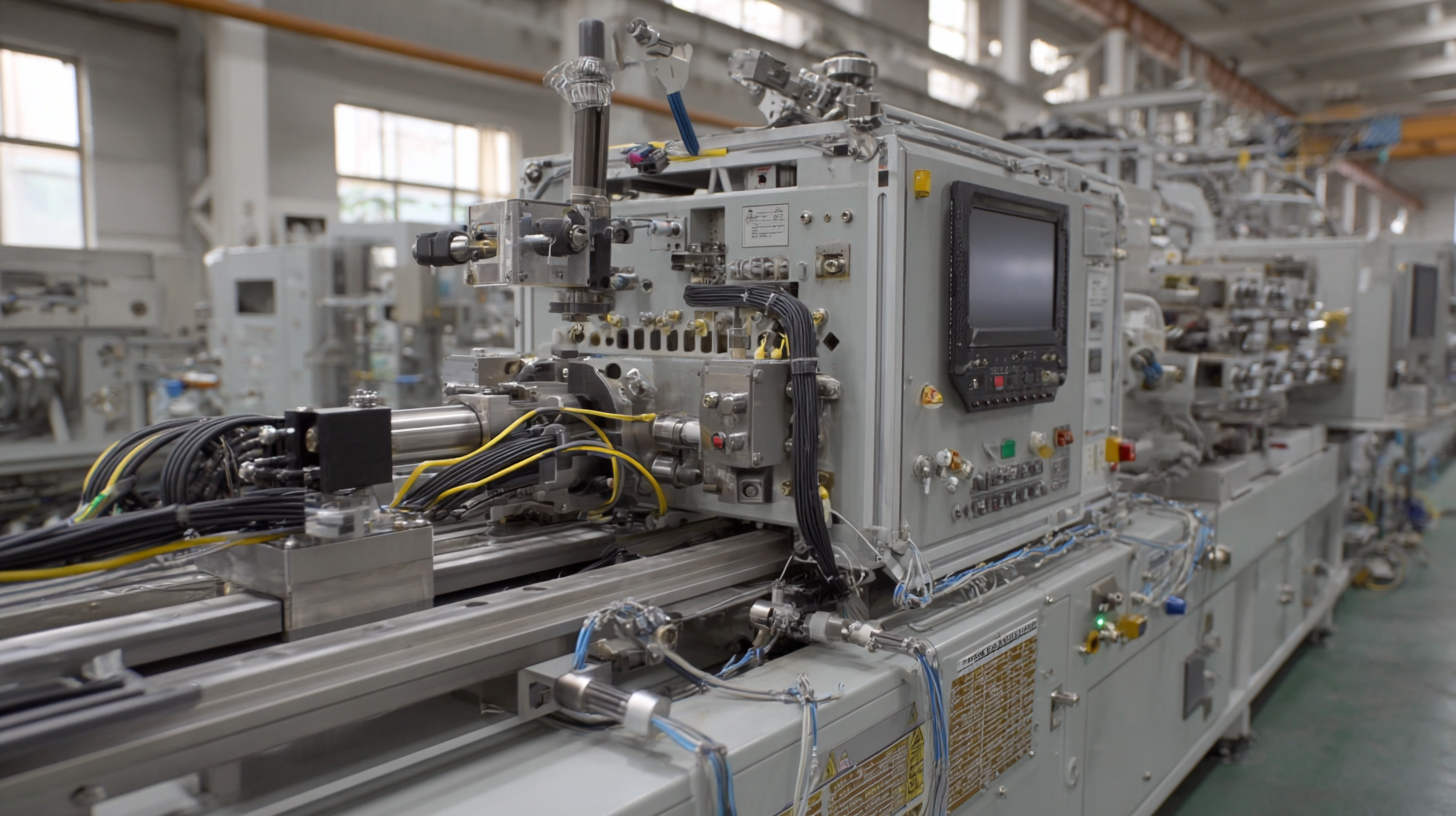

Another promising development is the integration of automation and artificial intelligence in extrusion processes. Smart extrusion technologies can optimize the parameters in real-time, ensuring consistent product quality while reducing energy consumption. By employing predictive maintenance and data analytics, manufacturers can significantly lower operational costs and enhance production flexibility. As global buyers explore these novel alternatives, they will find a wealth of options that not only meet market demands but also contribute to a circular economy in the plastics industry.

In 2023, the extrusions industry is witnessing a remarkable shift towards sustainability, as global buyers increasingly prioritize eco-friendly solutions in their procurement processes. The traditional plastic profile extrusion machines, while effective, often contribute to environmental degradation due to the heavy use of non-biodegradable materials. In response, manufacturers are exploring innovative alternatives, harnessing technologies that not only enhance production efficiency but also minimize ecological footprints.

One of the most promising trends is the integration of bio-based plastics in the extrusion process. These materials, derived from renewable resources, reduce reliance on fossil fuels and lower greenhouse gas emissions. Alongside this, advancements in recycling technology enable the reprocessing of plastic waste into high-quality feedstock for new extrusion applications. Buyers are now actively seeking equipment that supports these sustainable practices, reflecting a broader commitment to environmental responsibility in the manufacturing sector. As the market evolves, companies that embrace these changes are likely to gain a competitive edge, positioning themselves as leaders in the sustainable extrusion landscape.

The landscape of extrusion technology is evolving, especially with the advent of innovative materials that challenge traditional plastics. Recent studies highlight that implementing extra-wide deposition techniques in extrusion additive manufacturing significantly enhances interlayer mechanical performance by ensuring an extrusion width of at least 250 microns. This development is crucial as it marks a pivotal shift towards optimizing material properties and improving the overall strength of 3D-printed objects.

Additionally, the exploration of machine learning (ML) applications is revolutionizing the understanding of material properties in additive manufacturing. Research indicates that ML can be adeptly utilized to predict the hardness of quaternary polymer blends, facilitating performance-tunable materials. This predictive capability is vital in revolutionizing the selection of materials, offering manufacturers a pathway to customize their processes for improved mechanical robustness.

Furthermore, the establishment of a Circular Economy (CE) for plastics, particularly with materials like recycled polyethylene terephthalate (PET), emphasizes sustainability without compromising performance. The closed-loop recycling technologies underline the importance of reducing dependence on virgin materials while maintaining high performance in mechanically recycled materials. This shift is critical, as over 400 million metric tons of plastic waste are generated annually, demanding innovative solutions that marry functionality with environmental responsibility.

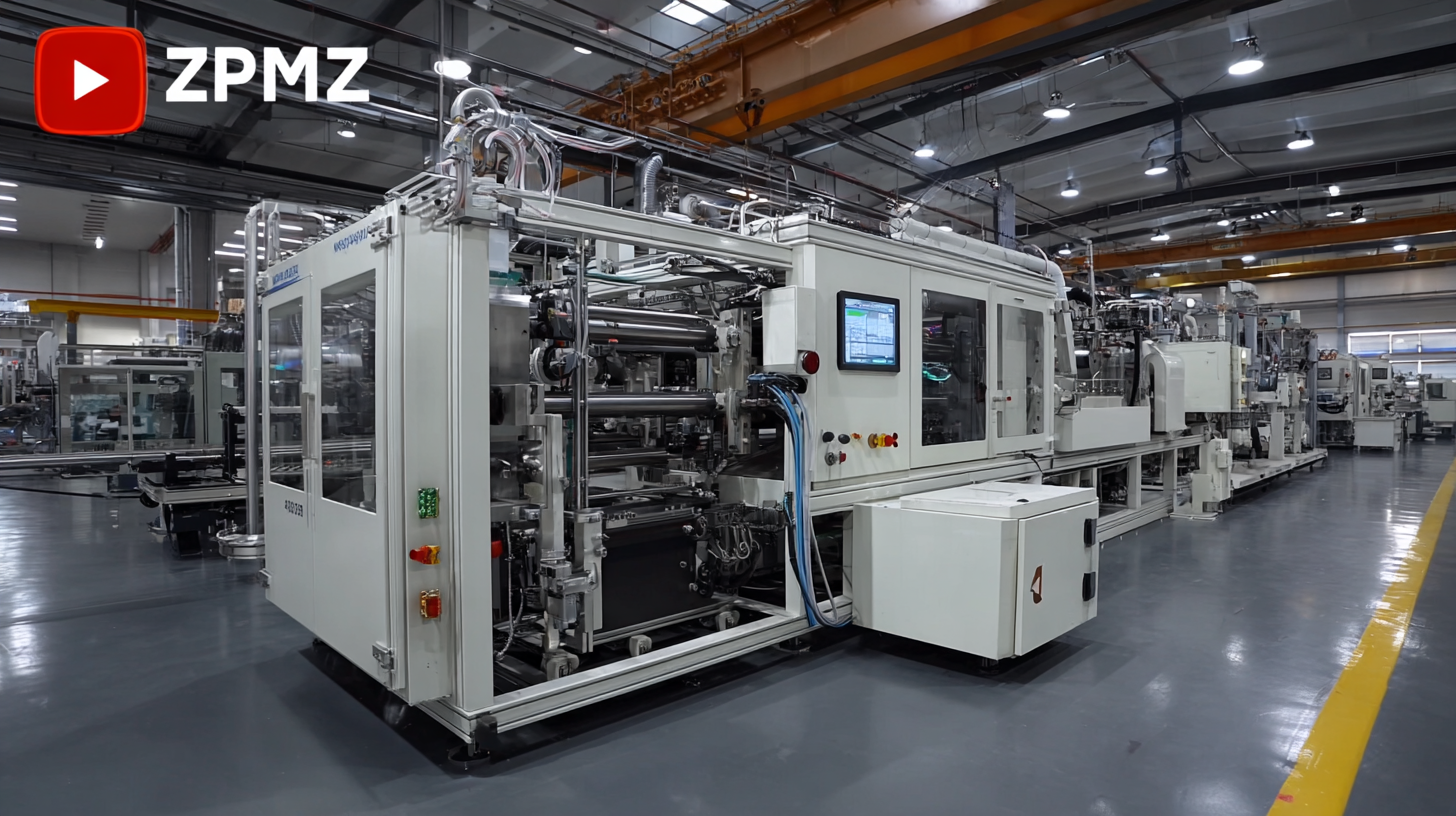

In the quest for cost-efficient manufacturing, global buyers are increasingly exploring alternatives to traditional plastic profile extrusion machines that dominate the market. According to a recent report by MarketsandMarkets, the global plastic extrusion market is projected to reach USD 36.62 billion by 2025, indicating a crucial need for cost-effective solutions. Buyers are now focusing on machines that offer not only efficiency but also sustainability, often considering technologies like twin-screw extruders and 3D printing for lower production costs and enhanced customization.

Tip: When evaluating alternatives, consider the initial investment versus long-term savings based on energy consumption, maintenance costs, and material efficiency. It's essential to look for machines that enable reprocessing of scrap materials, as this can significantly reduce waste and enhance profitability.

Furthermore, innovations in automation and IoT integration are providing buyers with advanced alternatives that improve overall operational costs. A study from ResearchAndMarkets highlights that automated extruders can reduce labor costs by as much as 30%, making them an attractive option for manufacturers seeking to enhance their production efficiency. Exploring these alternatives not only helps in reducing costs but also aligns with global sustainability goals.

Tip: Always request a total cost of ownership analysis from suppliers, which should include operational costs, potential downtime, and resale value to make informed investment decisions.

As the plastics industry evolves, the role of automation and artificial intelligence (AI) in profile extrusion innovation is becoming increasingly pivotal. These technologies promise to enhance production efficiency, reduce waste, and improve the quality of extruded profiles. Automated systems can monitor and adjust parameters in real-time, ensuring optimal performance that was previously unattainable with manual processes. AI algorithms can analyze production data to predict maintenance needs, thereby minimizing downtime and fostering a more sustainable production environment.

Tip: Consider investing in AI-driven monitoring systems for real-time adjustments. This not only enhances output quality but also extends the life of your machinery by preventing issues before they escalate.

Moreover, the integration of smart technologies paves the way for customizable extrusion solutions tailored to unique consumer demands. This adaptability allows manufacturers to quickly shift production lines in response to market trends, ultimately leading to a more resilient business model. With user-friendly interfaces, operators can efficiently manage the complexities of modern extrusion processes, transforming them from a daunting task into a streamlined operation.

Tip: Regular training workshops for your workforce on new automation tools can ensure that you maximize your investment in technology while keeping production agile and responsive.