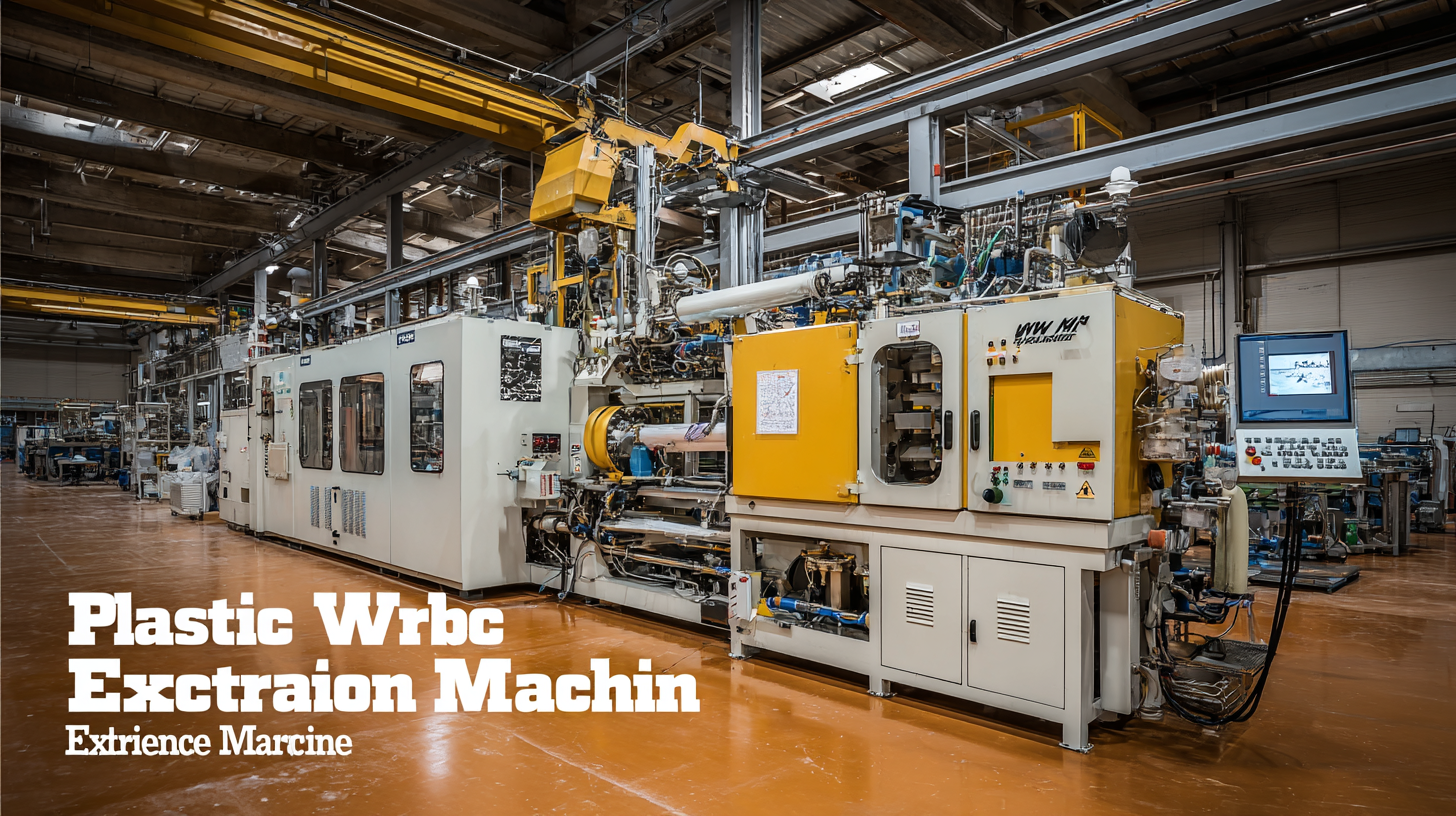

In today's rapidly evolving manufacturing landscape, the demand for efficiency and sustainability has never been more critical. The global market for Wood-Plastic Composites (WPC) is anticipated to reach $9.5 billion by 2027, growing at a CAGR of 13.4% from 2020 to 2027, according to a report by Fortune Business Insights. This surge highlights the imperative for manufacturers to invest in technology that can streamline production processes and improve product quality. Among these technologies, the Plastic WPC Extrusion Machine stands out as a pivotal tool capable of enhancing operational efficiency while minimizing waste. By optimizing the extrusion process, manufacturers can not only meet the increasing consumer demand for eco-friendly materials but also position themselves competitively in a global market that values innovation and sustainability. As such, exploring solutions for achieving peak efficiency with the best Plastic WPC Extrusion Machine is essential for stakeholders looking to capitalize on this burgeoning sector.

The global market for wood-plastic composite (WPC) products is rapidly expanding, and the efficiency of production processes plays a crucial role in meeting growing demand. WPC extrusion machines serve as the backbone of this industry, enabling manufacturers to produce high-quality materials while optimizing resource usage. By streamlining the extrusion process, these machines minimize waste and ensure consistent output, directly contributing to lower operational costs and increased profitability.

In today’s competitive landscape, manufacturers are finding that investing in advanced WPC extrusion technology is essential for elevating overall production efficiency. These machines come equipped with integrated features such as precision temperature control, adaptable feed systems, and automated process monitoring. Such innovations not only enhance the quality of the final product but also facilitate quicker turnarounds and flexible production runs. As brands strive to deliver sustainable solutions, the role of WPC extrusion machines becomes even more pronounced, allowing companies to meet both market demands and environmental standards effectively.

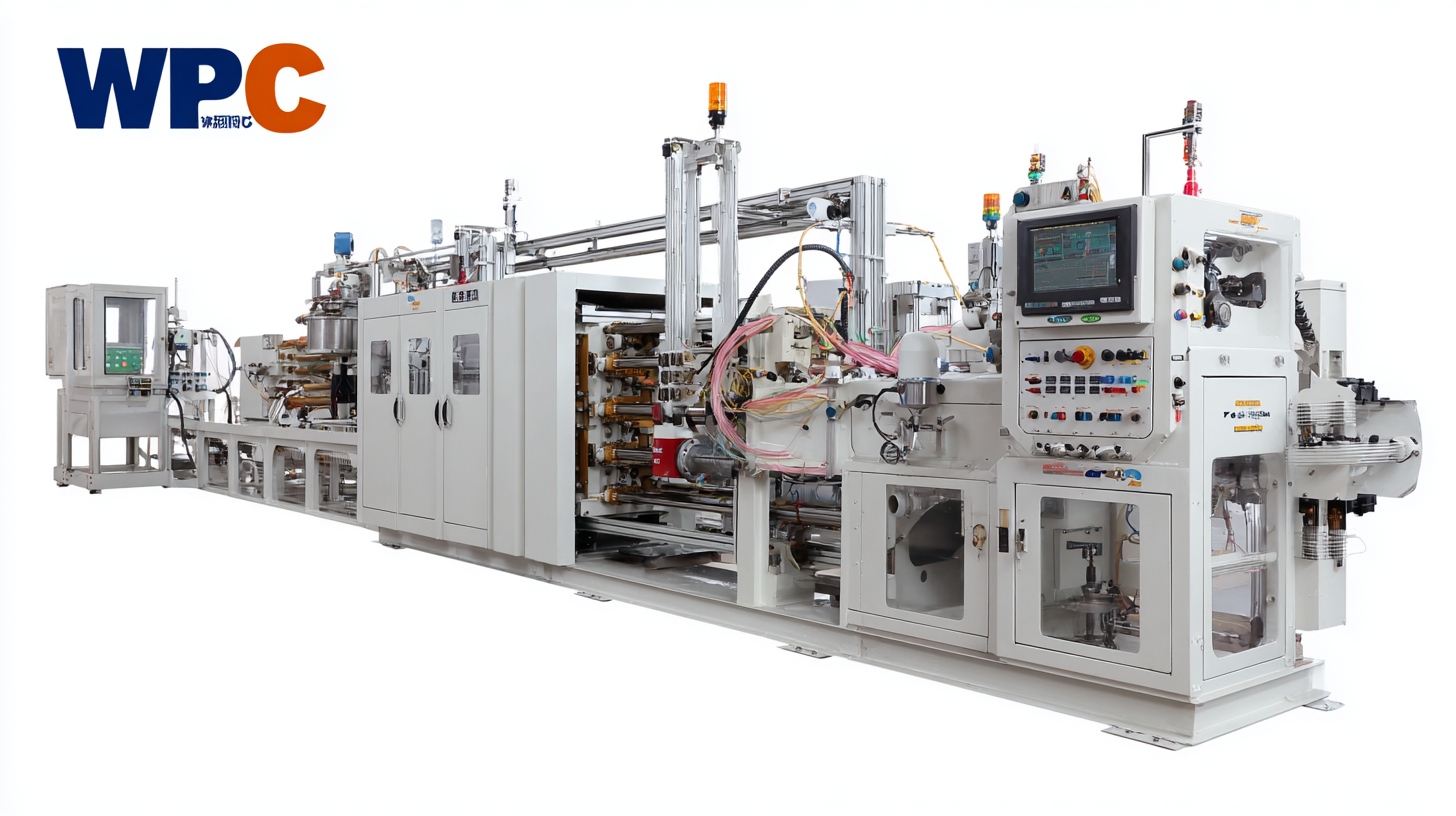

In the rapidly evolving world of WPC (Wood Plastic Composite) manufacturing, selecting the right extrusion machine is critical to achieving optimal efficiency. According to a report by Grand View Research, the global WPC market is projected to reach USD 12.31 billion by 2027, highlighting the increasing demand for high-performance machinery. Key features to consider in WPC extrusion machines include energy efficiency, throughput capacity, and versatility in material handling. Machines that incorporate advanced technology such as IoT connectivity enable real-time monitoring and adjustments, thereby reducing downtime and enhancing productivity.

Furthermore, the comparative analysis of various brands reveals that the most effective WPC extrusion machines offer a balanced combination of precision and speed. For instance, a performance study conducted by Mordor Intelligence indicates that machines with a twin-screw extrusion system typically outperform single-screw counterparts in terms of material mixing and consistency. Enhanced thermal regulation features are also vital, as they allow for better control of the extrusion process, leading to improved product quality. By investing in machinery that excels in these key areas, manufacturers can optimize their production lines and stay competitive in the growing WPC market.

As the global market for construction and design evolves, the demand for sustainable Wood Plastic Composite (WPC) solutions is on the rise. This shift is driven by increasing awareness of environmental issues and the need for materials that offer both durability and ecological benefits. Architects and builders are now prioritizing WPC not just for its aesthetic appeal but also for its performance advantages, making it a top choice for sustainable projects.

Tip: When selecting a WPC extrusion machine, look for models that offer precise temperature control and adjustable settings. This will ensure that you can produce WPC products that meet the specific needs of your projects while minimizing waste and maximizing efficiency.

The growing interest in sustainability is further supported by advancements in WPC technology, allowing manufacturers to create products that are not only eco-friendly but also versatile in design. With this trend, businesses are finding innovative ways to incorporate WPC in various applications, from decking and fencing to furniture and interior finishes.

Tip: Collaborate with suppliers who are committed to sustainability. This partnership can enhance your credibility in the market and provide you with access to high-quality materials that align with environmental standards.

The competition in the global market for Wood Plastic Composite (WPC) machines has intensified, particularly for Chinese manufacturers. Advanced technology plays a crucial role in enhancing the export competitiveness of these machines. Innovations such as automation, precision engineering, and real-time monitoring are transforming the traditional extrusion processes, enabling manufacturers to produce high-quality WPC products more efficiently and consistently. This technological upgrade not only streamlines production but also reduces waste and energy consumption, making Chinese WPC machines more appealing to international buyers.

Moreover, the incorporation of cutting-edge technologies has allowed Chinese manufacturers to diversify their product range, catering to various market needs. Features such as enhanced durability and customization options in extruded WPC materials are now possible due to advancements in machine design. As global demand for eco-friendly materials grows, these technologies position Chinese manufacturers to respond swiftly, thereby enhancing their competitiveness. With these innovations, Chinese WPC extrusion machines can now meet stringent international quality standards, leading to increased export opportunities and sustained growth in the global market.

| Dimension | Value |

|---|---|

| Extrusion Output (kg/h) | 400-800 |

| Energy Consumption (kW/h) | 50-150 |

| Machine Dimensions (m) | 3 x 1.5 x 2.5 |

| Weight (ton) | 5-10 |

| Materials Processed | Wood Plastic Composite, PVC, PE |

| Control System | PLC with Touch Screen |

| Market Reach | Asia, Europe, Americas |

| Export Growth Rate (Annual %) | 15-20 |

The global market for Wood Plastic Composite (WPC) extrusion machines is poised for remarkable growth, supported by an increasing demand for sustainable materials in construction and manufacturing. Recent statistical insights reveal that the market is expected to witness a compound annual growth rate (CAGR) of approximately 6% over the next five years. This growth can be attributed to the rising popularity of WPCs, which are not only environmentally friendly but also offer durability and aesthetic appeal, making them an attractive choice for various applications.

Moreover, regional market shares indicate that Asia-Pacific is projected to dominate the WPC extrusion machine sector, driven by rapid industrialization and the burgeoning demand for advanced construction materials. Countries such as China and India are leading the charge with significant investments in WPC technology, aimed at enhancing their manufacturing capabilities. Simultaneously, North America and Europe are also expanding their market presence, as sustainability initiatives push industries to adopt more eco-friendly practices. These statistical trends underscore the critical role of WPC extrusion machines in shaping a sustainable future in manufacturing and construction, making them essential investments for companies looking to enhance efficiency and market competitiveness.